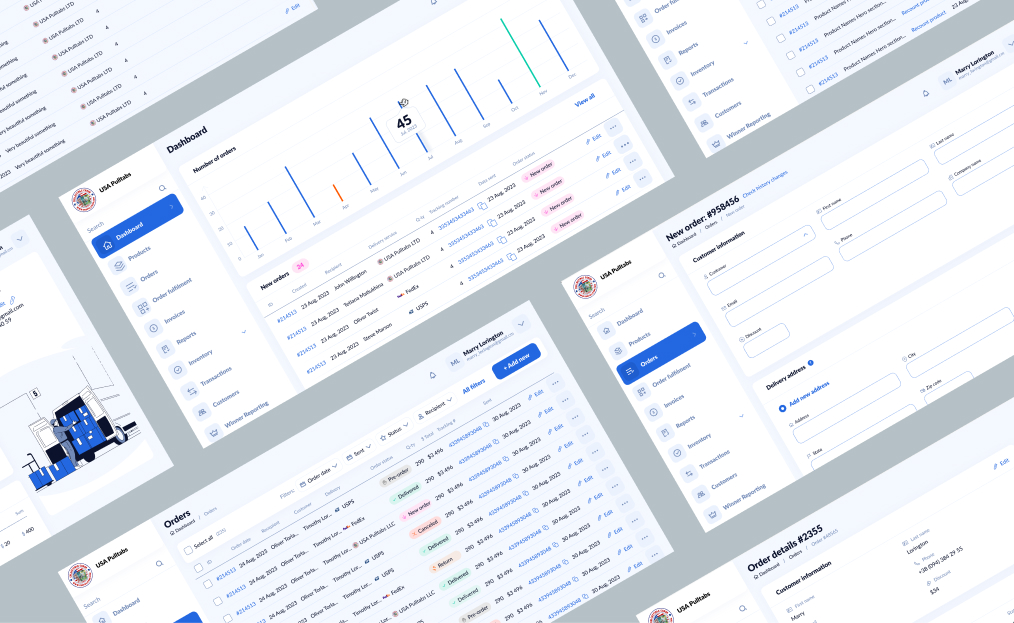

ERP system capabilities in practice

How we build ERP systems at Asabix?

Stages of work: from analytics to implementation

Every project begins with a thorough business analysis. We conduct stakeholder interviews, map out current processes (“as is”), and identify bottlenecks. Next, we design the target model (“to be”) with clearly defined roles and process scenarios. At the architecture stage, we select the right technological approach (modular or microservices) based on project scale and flexibility requirements. During the development of ERP systems, we integrate new modules with existing systems such as accounting, CRM, WMS, TMS, or others. Before go-live, each solution undergoes load testing and multiple rounds of data validation to eliminate potential failures. The final step is staff training. We create instructions and accompany the client at all stages of the process.

Tailored architecture for each business

We do not offer universal templates; each digital platform that we build is tailored to specific business processes. For manufacturing companies, it can be an integrated suite with MRP, MES modules and quality control systems that operate in a unified environment. We offer custom ERP systems development services with complex logistics for distributors, including automatic order allocation and a flexible pricing system. Logistics providers benefit from high-performance architectures capable of processing large data volumes, integrated with TMS and IoT trackers. Each solution is designed with future scalability in mind, enabling businesses to expand operations without rebuilding the entire system.

Technology stack

Our primary backend framework is Laravel, paired with REST or GraphQL APIs for external integrations. For complex cases, such as desktop application development, we also use .NET. On the frontend, we work with Vue.js or React to deliver fast, responsive interfaces. WebSocket ensures real-time data updates, critical for warehouses, production facilities, and dispatch centers. Redis serves as a caching layer to boost performance, while AI-driven automation helps cut development hours and streamline processes. For scalability and reliability, we rely on Docker containerization and Kubernetes orchestration. CI/CD pipelines enable seamless updates without system downtime.

Examples of custom modules

In production, we implement MRP for product release planning, equipment loading control, and waste accounting. For warehouse processes, ERP contains a WMS module with addressable storage, barcoding, and support for mobile terminals. The TMS logistics module provides optimal route calculations, GPS integration, and automatic transportation pricing. For financial departments, we develop dashboards with forecasts of P&L, cash flow and liquidity. HR modules allow you to automate change schedules, tabulation, and bonus calculations. Individual industry clients receive a claim management module with automatic SLA tracking and customer notifications. For those who want to get the most out of the data, we are adding AI analytics that predicts demand, identifies anomalies in financial flows, and suggests optimal purchasing strategies.

Stages of work: from analytics to implementation

Every project begins with a thorough business analysis. We conduct stakeholder interviews, map out current processes (“as is”), and identify bottlenecks. Next, we design the target model (“to be”) with clearly defined roles and process scenarios. At the architecture stage, we select the right technological approach (modular or microservices) based on project scale and flexibility requirements. During the development of ERP systems, we integrate new modules with existing systems such as accounting, CRM, WMS, TMS, or others. Before go-live, each solution undergoes load testing and multiple rounds of data validation to eliminate potential failures. The final step is staff training. We create instructions and accompany the client at all stages of the process.

Tailored architecture for each business

We do not offer universal templates; each digital platform that we build is tailored to specific business processes. For manufacturing companies, it can be an integrated suite with MRP, MES modules and quality control systems that operate in a unified environment. We offer custom ERP systems development services with complex logistics for distributors, including automatic order allocation and a flexible pricing system. Logistics providers benefit from high-performance architectures capable of processing large data volumes, integrated with TMS and IoT trackers. Each solution is designed with future scalability in mind, enabling businesses to expand operations without rebuilding the entire system.

Technology stack

Our primary backend framework is Laravel, paired with REST or GraphQL APIs for external integrations. For complex cases, such as desktop application development, we also use .NET. On the frontend, we work with Vue.js or React to deliver fast, responsive interfaces. WebSocket ensures real-time data updates, critical for warehouses, production facilities, and dispatch centers. Redis serves as a caching layer to boost performance, while AI-driven automation helps cut development hours and streamline processes. For scalability and reliability, we rely on Docker containerization and Kubernetes orchestration. CI/CD pipelines enable seamless updates without system downtime.

Examples of custom modules

In production, we implement MRP for product release planning, equipment loading control, and waste accounting. For warehouse processes, ERP contains a WMS module with addressable storage, barcoding, and support for mobile terminals. The TMS logistics module provides optimal route calculations, GPS integration, and automatic transportation pricing. For financial departments, we develop dashboards with forecasts of P&L, cash flow and liquidity. HR modules allow you to automate change schedules, tabulation, and bonus calculations. Individual industry clients receive a claim management module with automatic SLA tracking and customer notifications. For those who want to get the most out of the data, we are adding AI analytics that predicts demand, identifies anomalies in financial flows, and suggests optimal purchasing strategies.

Brands we work with

What is ERP, and when does a business need it?

ERP systems have become essential for companies that want to manage all processes from a single hub. At Asabix, we specialize in developing ERP software that integrates finance, logistics, manufacturing, and analytics into a single scalable platform. Let’s look at some examples:

Security and scalability as the foundation of ERP

Free consultation that saves you budget and months of work!

Our advantages

They trust us

We use the best

Technologies in our work

What our clients say frequently asked questions

ERP (Enterprise Resource Planning) is an integrated digital platform for managing key business processes in a single environment. It combines production, sales, finance, logistics, HR and other areas into one system with a single database. With the help of the platform, managers receive up-to-date information in real time, make decisions faster, reduce errors, and avoid data duplication.

We provide custom ERP software development services with a set of modules tailored to meet individual needs. These can be:

- MRP – production planning and control;

- WMS/TMS-warehouse and transport logistics;

- Financial modules – analytics, budgeting, cost control;

- HR – personnel management, time management, change planning;

- CRM – working with clients and transactions;

- Quality control – audit of products and processes;

- Claim work – accounting for complaints and service requests;

- Integration with marketplaces and banking systems.

The timeline depends on the size and complexity of the project. On average, a custom ERP implementation takes 4–12 months. The first weeks are dedicated to business analysis and architecture design, followed by ERP software development service, integrations, and testing. If you start with an MVP, a basic version can be launched in as little as 3 months, with additional functionality added later.

Ready-made solutions come with a fixed set of features, which often don’t align with your unique business processes. A custom ERP software development company builds software specifically around your workflows without unnecessary modules and with the flexibility to evolve. It integrates with your existing systems, follows industry standards, and meets local compliance requirements. Unlike boxed products, custom ERP development services are designed for scalability, support AI integration, and allow for interface customization and rapid adaptation to change.

The ERP development cost is formed taking into account the number of modules, the level of integrations and the amount of customization for specific business processes. Infrastructure plays a role: cloud platforms (Amazon Web Services or Microsoft Azure) or simpler hosting on providers like GoDaddy allow for a quick launch. If the project requires advanced features such as AI-driven modules, the price is higher.

ERP is an investment in productivity and profitability. Process automation reduces operational costs, reduces order fulfillment time, and minimizes errors. According to our projects, ROI occurs 12-18 months after implementation. In distribution, the effect is usually expressed in optimizing inventory and reducing logistics costs, reducing waste in production, and increasing the volume of work performed in service companies without expanding staff.

The Minimum Viable Product (MVP) version allows you to launch key modules faster and test their effectiveness in real-world conditions. For example, for a manufacturer, you can first implement MRP and warehouse accounting modules, and for a logistics operator, TMS with basic GPS integration and simple routing features. The gradual expansion of the functionality allows you to allocate a budget more efficiently and adapt the platform to user feedback.

AI transforms ERP from a record-keeping system into a strategic decision-making platform. Algorithms analyze large datasets in real time and recommend actions that directly improve profitability and efficiency. For businesses, this means:

- Faster response to market changes;

- Optimizing inventory and costs;

- Loss prevention;

- Improving the quality of service.

ERP is an integrated platform, so WMS (Warehouse Management), TMS (Transportation Management), and CRM (Customer Relationship Management) can be fully embedded within it. This gives you a unified environment to manage inventory, logistics, finance, and customer relations without data duplication. At the same time, we also develop WMS, TMS, and CRM as stand-alone systems if your company only needs to automate a specific area. In both cases, our ERP solutions development services ensure the architecture remains flexible, so you can continually expand it later with new modules or integrations.

.jpg)

-(1).jpg)

.jpg)

-(1).jpg)

.jpg)

.jpg)