Key CRM Capabilities in Manufacturing Business

Since 2017, we’ve been building CRM systems that streamline daily operations and make them more accurate. This frees up your time, allowing you to focus on business strategy and professional matters.

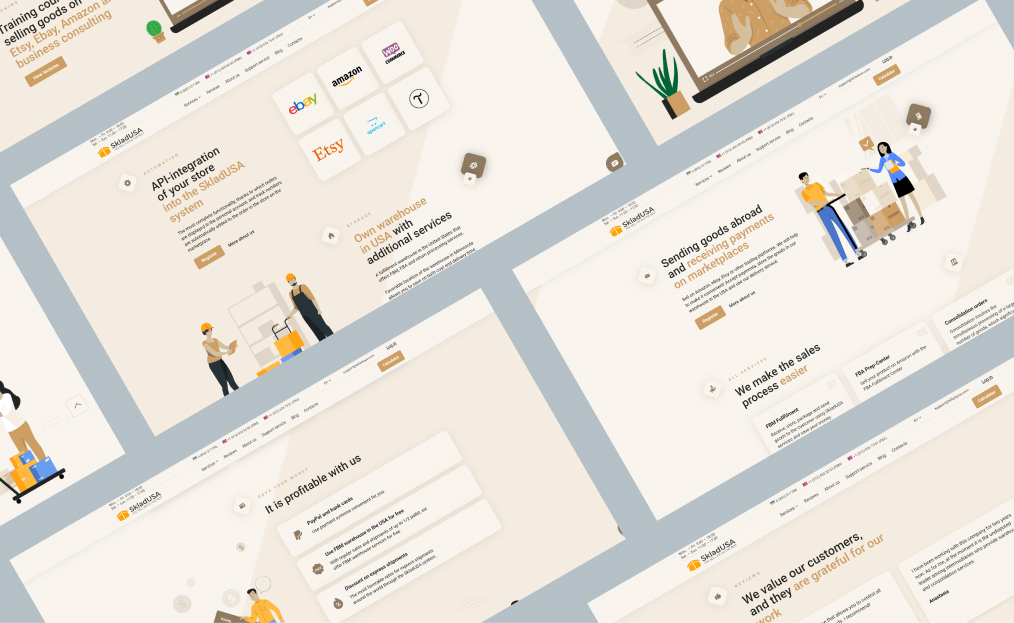

We will design a crm for manufacturing industry that syncs with logistics services or other systems you need. This way, managers will be able to track all orders, production dates, and shipment tracking. Additionally, we can integrate any API-supported service with the platform.

Which CRM solutions can be developed for industrial companies?

Custom development starts at $15,000. The final price varies depending on the number of required modules (such as production cycle management, warehouse management, and analytics), integration with other systems, and the number of users.

Operative digital system for your production

Pros:

- Fast loading

- Intuitive interface for your employees

- Fits seamlessly into your existing processes

- Ability to add new modules as needed

Comprehensive digital platform for automation

Pros:

- Automation of complex business processes

- Reduction of manual errors

- Analytics, planning, production forecasting

- Business scaling without chaos

CRM Functions for Production

CRM systems built on Laravel or ASP.NET ensure fast, reliable, and uninterrupted performance. The platform instantly responds to all business processes occurring in production. If you need a desktop version, we can also develop a manufacturing industry crm on .NET.

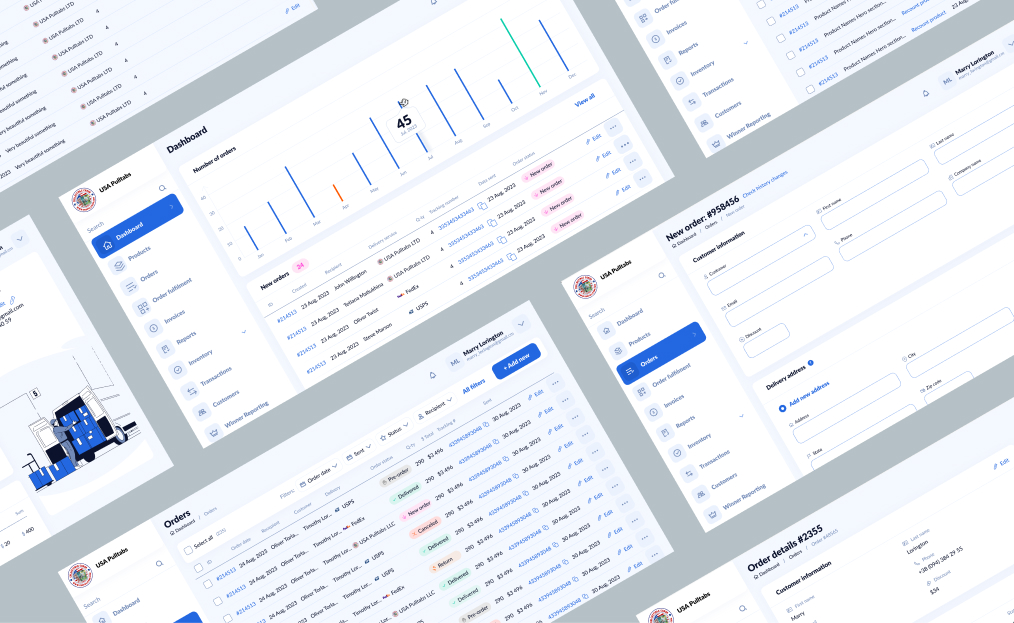

CRM will help you track every stage of the sales process. With just a few clicks, you can find the information, contact details, or an order you need. To achieve this, we employ a modular approach, where the code is divided into distinct components. Connections to BI platforms and mobile applications provide access to data anywhere, anytime.

A well-organized database in crm software for manufacturing improves production efficiency. We will design the database so that you can easily find the information you need, for example, by order, sales, or customers. This way, all data is stored in one place. It will prevent duplication of information and minimize errors.

Entrust these tasks to our CRM for production. It will be able to control the workload of workshops and resources, forecast demand, and coordinate work between different departments. You will get a unified work ecosystem that’s always within reach. Connecting IoT devices will enable you to monitor and manage production processes in real-time.

Why should you trust us with your CRM development?

We address common issues in this sector, including loss of order statuses, a lack of analytical data, and duplication of information in Excel. Based on this, our company creates a platform with clear functionality that helps automate rather than overload.

The CRM system for manufacturing contains only those modules that are relevant to you. We customize documentation, reporting, and production card formats according to your preferences. To ensure that the crm manufacturing software has a positive impact on business efficiency, we customize other settings according to your requests. Any changes in structure, products, or processes can be added whenever needed.

In addition, you have access to AI analytics that generate insights into the effectiveness of production shifts, the fulfillment of shop floor plans, inventory dynamics, logistics, and goods movement. If desired, we can also integrate AI models directly into CRM to optimize routine tasks and provide valuable insights for management.

They trust us

We use the best

technologies in our work

Frequently asked questions answered

The main difference is in the specific functionality and integration with production processes. While standard CRM focuses on sales, manufacturing CRM covers the entire order cycle. It also interacts with ERP, resource planning, and material accounting systems. It often takes several weeks or even months to close a deal in industrial business. CRM tracks every step and simultaneously forecasts the outcome. A standard accounting typically comes with ready-made templates, whereas a manufacturing CRM is usually created to meet individual requests.

Manufacturing crm solutions cover three core business needs: data centralization, process optimization, and results control. Additionally, the platform monitors workloads, generates reports, automates routine operations, and synchronizes the work of various departments.

Of course! Asabix will configure the platform to work in unison with your warehouse accounting, records, document flow, and logistics. This way, you avoid data duplication and gain a single ecosystem for your operations. Additionally, we can easily integrate any service that provides an API with your new CRM. As a result, your CRM will be universal and adaptive.

Development starts at around 4 months, depending on the complexity of your manufacturing CRM. We also take into account the time needed to prepare the necessary legal documents. First, we create a graphic design (the process takes several weeks). Then we develop and test the product. After each cycle, we provide you with the results, enabling you to track the process from start to finish.

This basic set of tools lets you manage orders and customer interactions. We can create an MVP solution for you with minimal functionality, such as a contact database, order status control, resource planning, and task setting. We also connect integrations with GPS, ERP, IP telephony, accounting, email/SMS mailings — everything you need for convenient work. This way, you get an effective solution without unnecessary costs. Later, you can scale up and integrate other modules, such as customer accounts, analytics, and finance.

Ready to get started?

Reach out to us!

Ukraine, Zhytomyr

Vitruka Street, 9V

Mon – Fri, 9 am – 7 pm

Poland, Warsaw, 00-842

Łucka Street 15/204

Mon – Fri, 9 am – 7 pm

.jpg)

.jpg)

-(1).jpg)

.jpg)

.jpg)

.jpg)