Developing a Production Management System (MES) for Artmash

About the client

Artmash is a Ukrainian manufacturer of agricultural equipment, including pelletizers, log splitters, feed mixers, and augers, designed for use in farming and livestock operations. The company manages the entire production cycle using CNC machinery and supplies products to dozens of countries, consistently incorporating innovations into its high-volume manufacturing processes.

To optimize their seasonal production and eliminate manual management, Artmash partnered with the Asabix team.

About the product

As Artmash scaled its business, it needed a digital system to consolidate order processing, production operations, and logistics into a single environment. A lack of end-to-end coordination and overreliance on Excel resulted in inefficiencies, errors, and disruptions to planning.

After thoroughly analyzing their processes, the Asabix team built a platform that closely reflects Artmash’s real-world operations. This includes route sheets, multi-level processing, synchronized warehouses, and logistical routes. Every stage of production is now integrated into a single transparent management system.

Key Challenges

Create a centralized digital system to coordinate all production processes, covering every stage from order intake to final product delivery.

Replace manual Excel and paper-based reporting with controlled, logically linked digital workflows, and implement automatic formatting of analytics based on required parameters.

Ensure seamless interaction among the sales, procurement, and accounting departments.

Design dynamic part processing routes that consider product type, processing stages, and workshop capacity.

Ensure seamless transfer of drawings and technical instructions from the design team to operators, with no loss, unauthorized edits, or outdated versions.

Enable full traceability of parts throughout all production stages, including status updates, progress checkpoints, and assigned personnel logs.

Establish a hierarchy of roles and access rights to ensure that each employee has access only to the functions relevant to their role.

Develop a real-time analytics dashboard to track order fulfillment, downtime, exceptions, and current workload.

Design a minimalist, intuitive interface for employees at all levels.

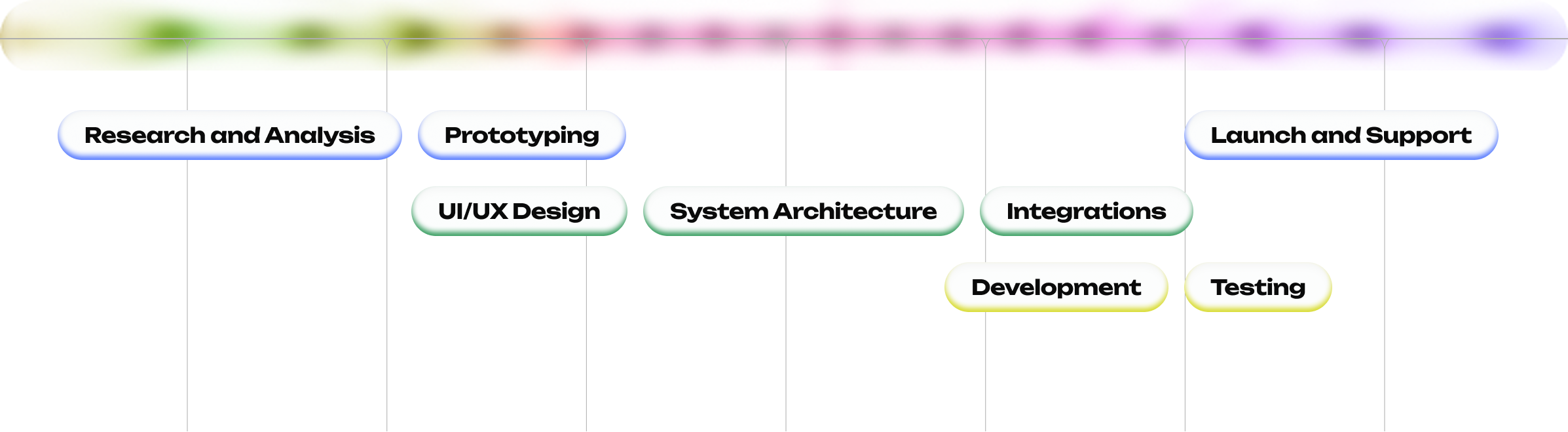

Technology stack

and approach

We designed the system using a proven tech stack built to handle industrial-level demands.

The architecture is modular, user roles are clearly defined, and interfaces are simplified to just 2-3 clicks. The system is scalable and ready to integrate new workshops or processes without requiring core changes.

Laravel for implementing business logic and integrations.

Vue.js for building the adaptive interface.

Figma for interface design, accounting for user roles.

KeyCRM (two-way data exchange), Excel import/export.

Redis for event caching; Elasticsearch for fast searching across the database of drawings and routes.

A web application with a scalable client-server structure.

A cloud environment for centralized access and scalability.

Our solution

We developed a comprehensive MES/ERP system for production management, integrating route cards, technical documentation, orders, batches, and warehouse stock into a unified environment.

We linked each product to its drawings, route card, and production task, ensuring workers have up-to-date instructions and precise specifications at every operational stage.

We implemented automatic route generation based on product type, allowing production to be launched directly from the system. This includes creating document packages, generating QR codes, and assigning them to operators.

We implemented inventory control, reservation, and smart material allocation across production batches, based on priority, availability, and material requirements.

We enabled automated alerts for material shortages along with real-time optimization suggestions.

We developed a time-tracking module, enabling the recording of actual work duration and the analysis of productivity by employee and section.

We created a change log for technical documentation and drawing revisions to ensure version accuracy and data integrity.

We designed a simple interface for production personnel with intuitive navigation.

We ensured centralized logging of all actions, enabling auditing and control.

We set up two-way integration with KeyCRM for exchanging orders, statuses, and other data, along with Excel import/export functions for quick initial processing.

Business results

- Reduced workload for technologists by automating route cards and task creation.

- Decreased production errors due to linking drawings and technical specifications directly to specific products.

- Simplified material control through digitized inventory management.

- Increased profitability by saving master technicians' time, automating reporting, and reducing defects.

- Increased production line efficiency without adding headcount, as the system automatically organizes workflow priority and load.

- Production processes became fully transparent, providing management with real-time visibility into the status of each order.

- Achieved reliable production forecasting, as the platform now calculates output volumes and delivery timelines for customers.

Summary

The Asabix team developed a CRM/ERP system that synchronizes production routes, drawings, and warehouse stock, fully adapting to complex seasonal dynamics.

The platform is intuitive, easy to use, and performs smoothly on any device, including smartphones and tablets.

Want to transition your production from manual operations to a managed, transparent system?

Contact us, and we'll build a solution that's a perfect fit for your business.